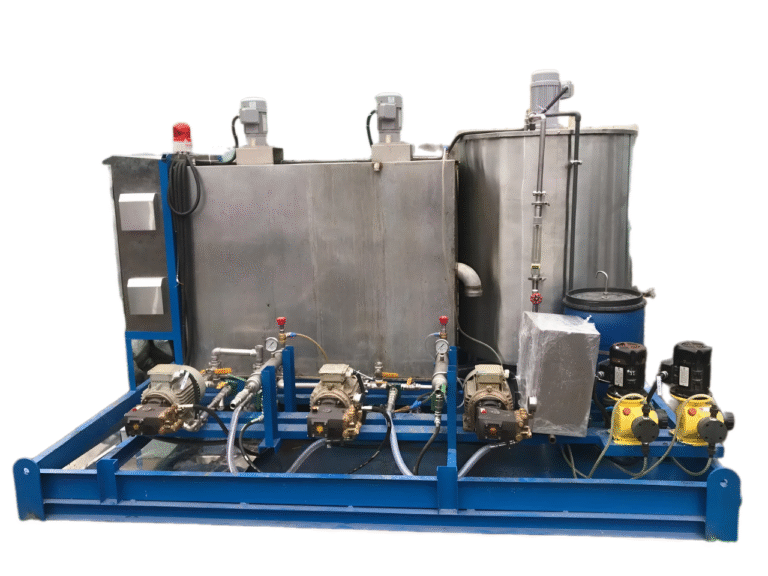

Dry Material Feeder – Precision Feeding for Maximum Efficiency

Looking for a reliable solution to feed dry materials with accuracy and consistency? The Dry Material Feeder is your go-to system for optimizing production lines across industries.

Key Features

-

Accurate Dosing: Provides continuous or batch feeding with precise control of flow rate.

-

Versatile Design: Handles a wide range of materials—from fine powders to coarse granules—without clogging or bridging.

-

Dust Control: Enclosed construction reduces material loss and keeps the work area clean.

-

Robust Construction: Available in carbon steel or stainless steel (304/316) for chemical, food, or water-treatment applications.

✅ Why Choose the Dry Material Feeder?

- High Precision Feeding: Delivers powders, granules, and pellets with exact flow control, minimizing waste and maximizing output.

- Fully Automated Operation: Reduces manual labor and ensures consistent performance.

- Compact & Versatile Design: Easy to install and integrate into existing production systems.

- Durable Construction: Built with corrosion-resistant materials to withstand harsh industrial environments.

🔧 Ideal for Multiple Industries

The Dry Material Feeder is widely used in:

-

-

Water & Wastewater Treatment: Automated feeding of dry polymers, lime, or PAC.

-

Chemical & Pharmaceutical Industries: Accurate delivery of chemical powders and additives.

-

Food & Beverage Processing: Metering flour, sugar, spices, or other dry ingredients.

-

Plastics & Rubber Production: Feeding resin pellets and powdered fillers.

-

📈 Boost Productivity & Cut Costs

With continuous and accurate feeding, this system helps:

- Reduce material loss

- Improve product quality

- Enhance production speed

- Lower operational expenses

📞 Contact Us Today!

Upgrade your production line with the Dry Material Feeder – the smart choice for modern manufacturing.

📧 Email: sales@anlocphat-tech.com

🌐 Visit: www.anlocphat-tech.com